Strips - Ribbed polar grade PVC curtain

STRIPS Strip curtains

The heat-insulating strip curtains are a simple but inexpensive and effective solution for thermal separation. We only use cold-resistant components.

A special profile in the strip material ensures that the strips do not stick together even when ice forms, as an air cushion is ensured.

The transparent PVC strips enable people and vehicles to pass through quickly and without obstacles.

The PVC curtains are maintenance-free. When passing through, the curtains close immediately, reducing the amount of heat flowing in and out to a minimum and saving energy.

A thermography shows it:

With a strip curtain - a clearly recognizable reduction in the thermal bridge on the left-hand side of the hold. In this way, the unwanted gas exchange during loading and unloading can be reduced by more than 50%.

The systems are suitable for the thermal insulation of heated and unheated rooms. They offer protection against drafts, noise and dust and represent additional health and work protection. The cheapest way to separate off the cargo space or your warehouse.

Also for cold stores, warehouse locks and passageways.

Or available as a

3-part panel curtain.

Panel curtain as

Slide Shift 3D version & 3 channel track for Shift version

Pre-assembled

Fix Shift transverse track with slide

and carriage

Storrwall Strip Curtain options

Fix

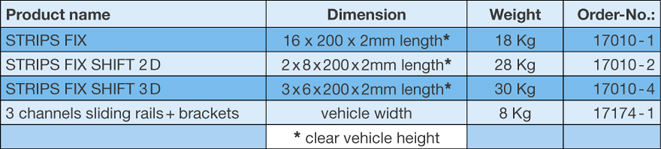

Version fixed in the rear or in the vehicle mounted on a stainless steel hook strip for wall or ceiling mounting, 18 strips 200 x 2.0mm with 50mm overlap, length is adapted to the individual vehicle situation after installation.

Fix Shift

Like the fix version, fixed at one point, only with transverse displacement / carriage 2D or 3D version, guided in aluminum STORR rails with brackets for mounting on the side wall to enable removal during repairs.

Installation of the 3-channel running rail fixed in the rear portal using aluminum brackets with slotted holes. When the ready-made curtain systems are delivered, the assembly is already pre-made to the inside dimensions of the vehicle / portal; the angles only have to be riveted, glued or screwed in the area of the side walls. Assembly time only 20 minutes depending on the portal version.

In the event of repairs, the slides and the 3-channel rail can be easily removed and the components checked and replaced if necessary. Up to the ceiling / portal, the profile is supported and sealed with PE strips.

Slide

In the sliding version, the separation is fixed to a trolley that runs in the longitudinal direction of the vehicle in a STORR rail. Additional STORR rails are required for installation in the vehicle.

Slide Shift

In the sliding version, the separation is fixed to a trolley that runs in the longitudinal direction of the vehicle in a STORR rail. Mounted with transverse displacement / carriage 2D or 3D version, guided in aluminum STORR rails. Additional STORR rails for installation in the vehicle are required for longitudinal displacement.